Cat® Undercarriage Options for Small, Medium, and Large Excavators

We offer more undercarriage options for your Cat® machines than any other manufacturer because we know that the more precisely you match iron to application, the more effective and effcient your work will be. Whether you’re looking for the lowest upfront cost, longer wear life or lower operating costs per hour, we have the right undercarriage solution for your business.

Every Cat Undercarriage is designed by Caterpillar engineers and built to exact specifcations based on the real-world experience of our customers. And our Undercarriage systems come with industry- leading warranties, so when you choose a Cat Undercarriage you know it’s not just the right choice, it’s the best choice.

UNDERCARRIAGE SELECTION MATTERS

One of the most important factors in helping you achieve the lowest owning and operating costs and maximizing equipment uptime is matching the right undercarriage option to your specifc machine model and work application.

|

KEY SELECTION FACTORS TO CONSIDER |

||

|

|

TRACK FRAME CONFIGURATION |

Standard (STD), Long (L), Long Narrow (LN), Reduced Radius (RR), Long Reduced Radius (LRR) |

|

|

WIDTH OF TRACK SHOES | Narrow, intermediate or wide |

|

|

UNDERFOOT CONDITION | Light, moderate or severe abrasion and impact |

|

|

TERRAIN | Slope conditions, size and type of material |

|

|

PACKING CONDITIONS |

Operating in extrudable materials, which can usually be squeezed out from between track parts when wet, for example, clay soils Operating in non-extrudable materials, which can’t be extruded from the link windows and track shoe center holes of most undercarriage tracks, for example, branches |

|

|

APPLICATION |

Digging, hammering, or moving rocks |

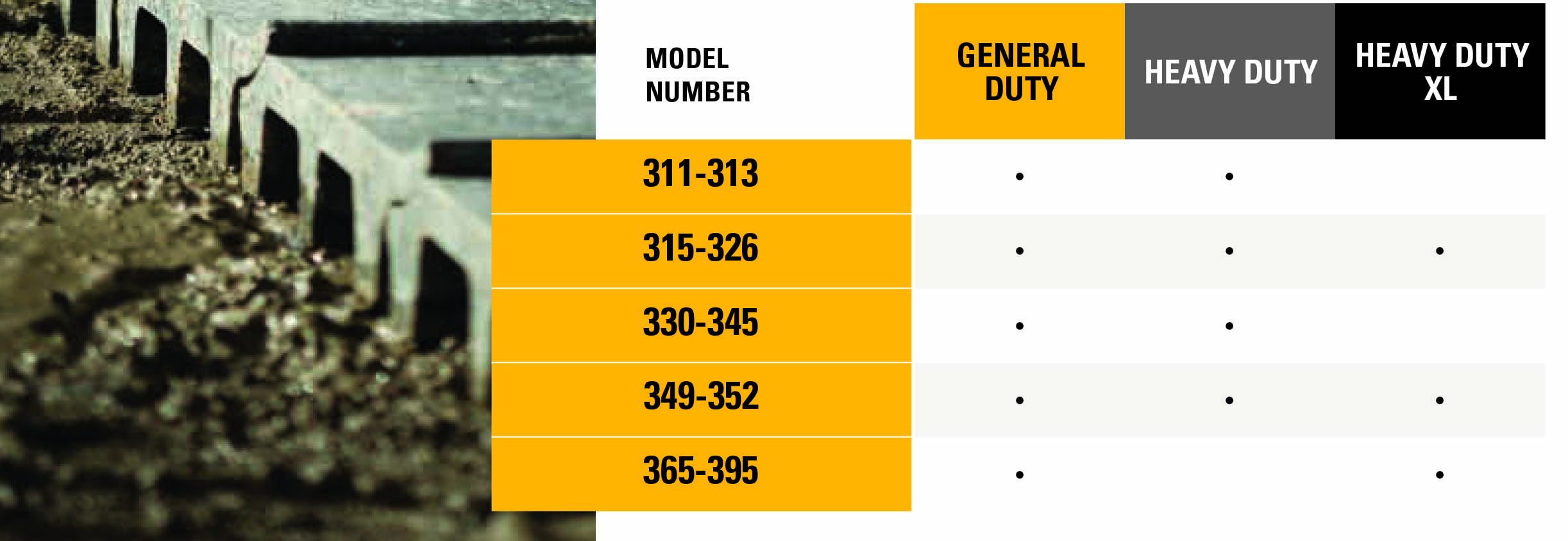

HYDRAULIC EXCAVATOR COMPATIBILITY

CAT GENERAL DUTY TRACK

PERFORMANCE YOU CAN COUNT ON General Duty undercarriage, a Grease Lubricated Track (GLT), for low-to-moderate impact applications where the elevated performance of the Cat Heavy Duty track undercarriage is not needed.

INTERCHANGEABLE COMPONENTS

While General Duty track is built to different specification than Heavy Duty, Cat design it so General Duty and Heavy Duty components are interchangeable. That eliminates any need for retrofitting and keeps your machine downtime to a minimum.Additionally, Cat Heavy Duty shoes can be installed on General Duty link assemblies, making them more flexible to meet your needs.

PARTS WHEN YOU NEED THEM

We have General Duty parts stocked and available for fast turnaround, keeping you and your machine working.

A VARIETY OF OPTIONS

A variety of track shoe options are offered for General Duty. In addition to undercarriage components, track shoe selection can impact traction and flotation as well as overall undercarriag wear life. For the conditions in which General Duty Undercarriage will typically operate, moderate service shoes offer optimal performance and wear life. (General Duty Hydraulic Excavator preassembled track groups are available)

CAT HEAVY DUTY UNDERCARRIAGE

- Heavy Construction

- Pipe Laying

- Demolition

- Scrap Handling

- Forestry

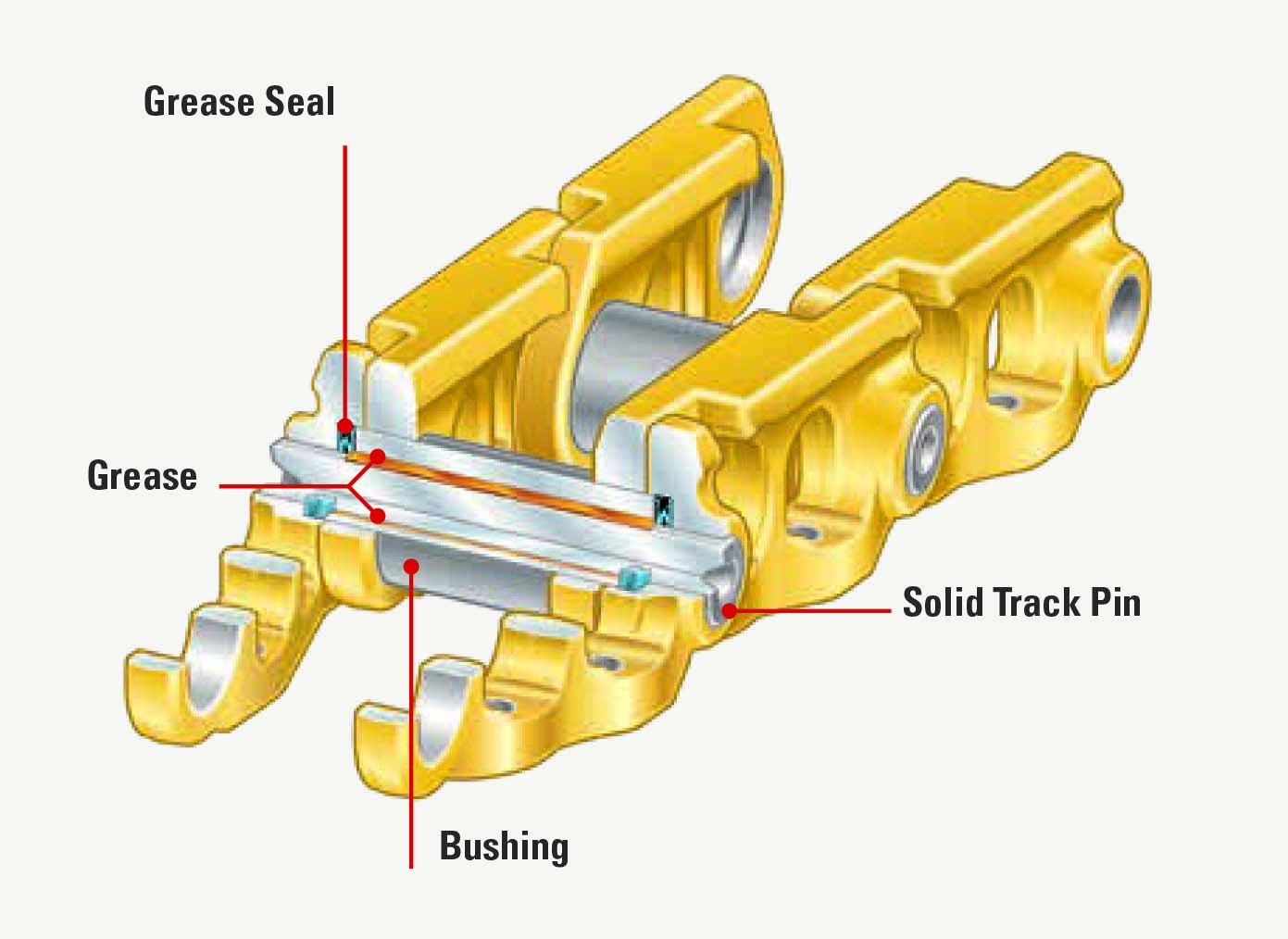

Each track joint is sealed to retain the grease between the pin and bushing to minimize internal wear with our Grease Lubricated Track (GLT) technology.

CAT HEAVY DUTY XL TRACK

Maximum durability in tough conditions with extended wear life and lower operating costs. Proven Cat Heavy Duty design with the addition of stronger Duralink and Positive Pin Retention 2 (PPR2) achieves best results in high-impact and high-travel applications such as mining, heavy construction, pipe laying, demolition, and scrap handling. PPR2 is an exclusive Caterpillar offering that mechanically locks the link to the pin to handle the toughest conditions.

INCREASED TRACK LIFE

Resists pin walking and link cracking for reliableResists pin walking and link cracking for reliable sealing and maximum track life

LONGER WEAR CYCLE

Tightly controls seal motion for long internalTightly controls seal motion for long internalpin/bushing wear life

STRONGER TRACK LINKS

Resists fatigue & crack formation withResists fatigue & crack formation withredesigned, stronger track links

UNDERSTANDING LUBRICATION

With Grease Lubricated Track, internal wear is eliminated until the grease dissipates from the line assembly.

Without Grease Lubricated Track, internal pin and bushing wear begins immediately because of contact and friction between the two parts. Grease Lubricated Track contains grease between the pin and bushing to eliminate the contact and friction wear elements.

This results in a significant increase of internal wear life of the link assembly.

CLAMP MASTER FOR HYDRAULIC EXCAVATORS

Dig deeper & save time and money with a clamp master design that makes track installation safer and easier.

Caterpillar’s new Clamp Master saves you time and money by making track installation on most models of Cat Hydraulic Excavators safer and easier than ever. The improved clamping master tracklink assembly replaces both slip style and press fit joints. With thisinnovative design, use of a portable field press is unnecessary—which means you get back to work faster.

INCREASED SERVICEABILITY

Improved master joint that addresses durability andImproved master joint that addresses durability andserviceability in a single design

STRONGER PIN RETENTION

25% better pin retention than a press fit master,25% better pin retention than a press fit master,removing the risk of damage to the cotter pin

NO SPECIAL TOOLS

Eliminates the need for a portable field press. No specialEliminates the need for a portable field press. No specialmaster pin required for track master link.

WIDE APPLICATION

Available for any standard hydraulic excavator in 7.5”Available for any standard hydraulic excavator in 7.5”pitch size class (315-326)

CAT UNDERCARRIAGE SUPPORT

COMPREHENSIVE SUPPORT

To help you get the most from your Cat Undercarriage, Caterpillar and Cat dealers are dedicated to providing you with global service andsupport for all undercarriage configuration options—from advanceddiagnostics to worldwide parts delivery.

UNDERCARRIAGE ASSURANCE PROGRAMS

Our Undercarriage Assurance Programs were developed to demonstrate our commitment to provide you the lowest cost-per-hour undercarriage systems. Assurance Programs offer you support beyond the standard new machine or parts warranties. They cover all major moving undercarriage components on Cat track-type tractors, track type loaders and track-type hydraulic excavators.Contact us for full details about coverage for specificundercarriage configuration options.

CUSTOM TRACK SERVICE (CTS)

An improperly managed undercarriage can cause downtime and account for more than half of machine maintenance costs. That’s why we use the most advanced diagnostic equipment available to provide Custom Track Service (CTS) for maintaining your undercarriage system.With CTS, we can accurately monitor undercarriage performance and predict wear rates so you can evaluate service options, plan maintenance, and fit downtime into your schedule. And because CTS analysis can be completed on the job site, you can make informed decisions that keep your operating costs as low as possible, without sacrificing uptime.

WORLDWIDE PARTS AVAILABILITY

Our industry-standard parts distribution network makes most newparts available to you anywhere in the world, usually within 24 hours.

Terms & Conditions

- Applicable only to Cat equipment owners in Singapore.

- Applicable only to specific Cat parts.

- Parts purchased under promotion are non-returnable and non-refundable.

- Parts are subjected to prior sales. Any miscellaneous charges, such as airfreight or emergency charges, will be incurred by customers unless order under non-emergency basis.

- Not valid with other promotions or discounts.

- Offer valid until 26 Jun 2026 and subject to parts availabilities or while stock last. Any back order parts that are confirmed and delivery after 26 Jun 2026 will be subjected to the new pricing.

- Other terms & conditions for quotation and sales order apply.

- Tractors Singapore Limited reserves the right to modify or cancel the program anytime

Speak With Us And Find Out Which Undercarriage Option Suit Your Machine The Most.

Because at Tractors Singapore, we ensure that you get the best advice and service from our highly skilled dealer specialist to keep your equipment performing at its best.