Cat® Grease Cat Grease uses advanced thickening agents, so grease stays where you put it.

Selecting the right grease for machine maintenance may appear inconsequential, but it can significantly influence your business, impacting equipment performance, uptime, and overall profitability.

Why use Cat® Grease?

01 Improved corrosion protection resulting in an extended component life.

Resists oxidation and safeguards metal from rust.

02 Superior protection for even the most extreme environments.

Unique thickener and additive blends provide enhanced protection for the required application.

03 Optimal equipment protection leads to reduced operating costs.

Cat Grease keeps equipment running smoothly and reliably.

Case Study

Why pay more for grease?

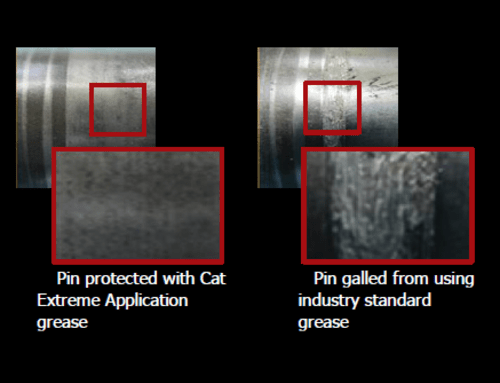

Justifying the purchase of premium grease is challenging when the distinction between good and bad grease is not apparent. However, when testing greases in a demanding application, the contrast becomes evident.

Pictures show actual results from a Cat® 329 HEX pin and bushing test. Cat Grease and a leading competitor’s grease ran side by side for the duration of the test.

OUTCOME

- 5x less grease consumption.

- Lesser time spent greasing compared to other grease.

BENEFIT

- Reduced greasing by 5 times means skipping 7 days of greasing annually, providing an additional week of machine uptime.

- This increased production for 7 days a year translates to an extra week of profit.

Options for Cat® Grease

01 Cat Extreme Application Grease 2

- For high-load, high-speed applications operating between -15°C to 140°C

- NLGI 2

- Calcium sulfonate complex formula with 5% moly for long service life

- Moisture resistance — resists washout from fresh and salt water

02 Cat Ball Bearing Grease

- For high-speed ball and roller bearing applications operating between -20°C to 160°C

- NLGI 2

- Formulated with polyurea thickener and corrosion inhibitors

- Heat resistance provides improved protection, reducing component wear rates.

03 Cat Prime Application Grease

- For medium-load, medium-speed applications operating between -20°C to 140°C in low moisture environment

- NLGI 2

- Lithium complex grease, enhanced with 3% moly

- Standard factory-fill for most Cat equipment