Cat® Filters Go Genuine with Cat Filters

No matter when or where Cat® filters are purchased they have the same consistent high quality. Because Cat filters are made better, they provide consistent performance to protect your engine, drive train, and hydraulic systems. While other brands may fit, Cat filters offer the superior quality and protection you need to maximize your engine and other component system's life.

The Difference Is Clear

Other brands may fit, but Cat filters protect your engine, drive train and hydraulic systems and components better. Our advanced design delivers maximum filtration efficiency and protection for your equipment. For you, that means more uptime and lower owning and operating costs.

A: No Flexing

Spiral Roving

- Reduces pleat fex and fatige

- Maximizes media surface utiizatio

- Increases contaminate retenton

B: No Bunching

Acrylic Beading

- Prevent bunching

- Maximizes media surface area utiizatio

C: No Metal Contamination

Non-Metallic Center Tube

- Stronger than metal

- Maximum cleanliness

D: No Gaps

Urethane End Caps

- One-piece design

- Media molded into urethane

- Eliminates possible leak paths

THE BEST MACHINES DESERVE THE BEST FILTERS

Don’t risk your investment by using other filter and fluid brands. Only Cat filters and fluids are developed, tested and approved to the exacting standards of Cat equipment.

AIR FILTERS

Safeguard your equipment and

operators from dirt and contaminants.

HYDRAULIC & TRANSMISSION FILTERS

Extend hydraulic and power train component life

by reducing contamination.

ENGINE OIL FILTERS

Keep engine parts functioning properly to

avoid efficiency loss and failure.

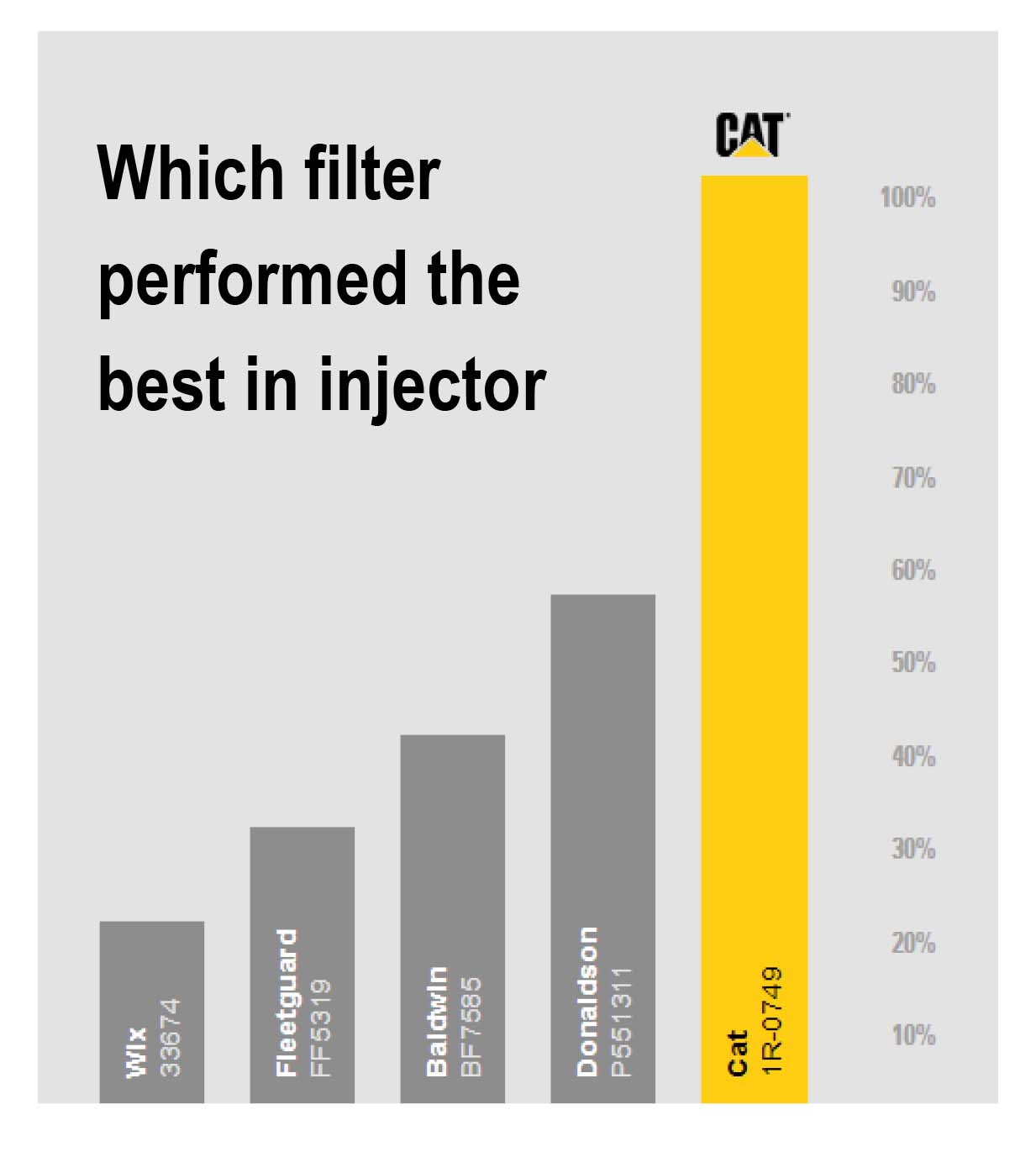

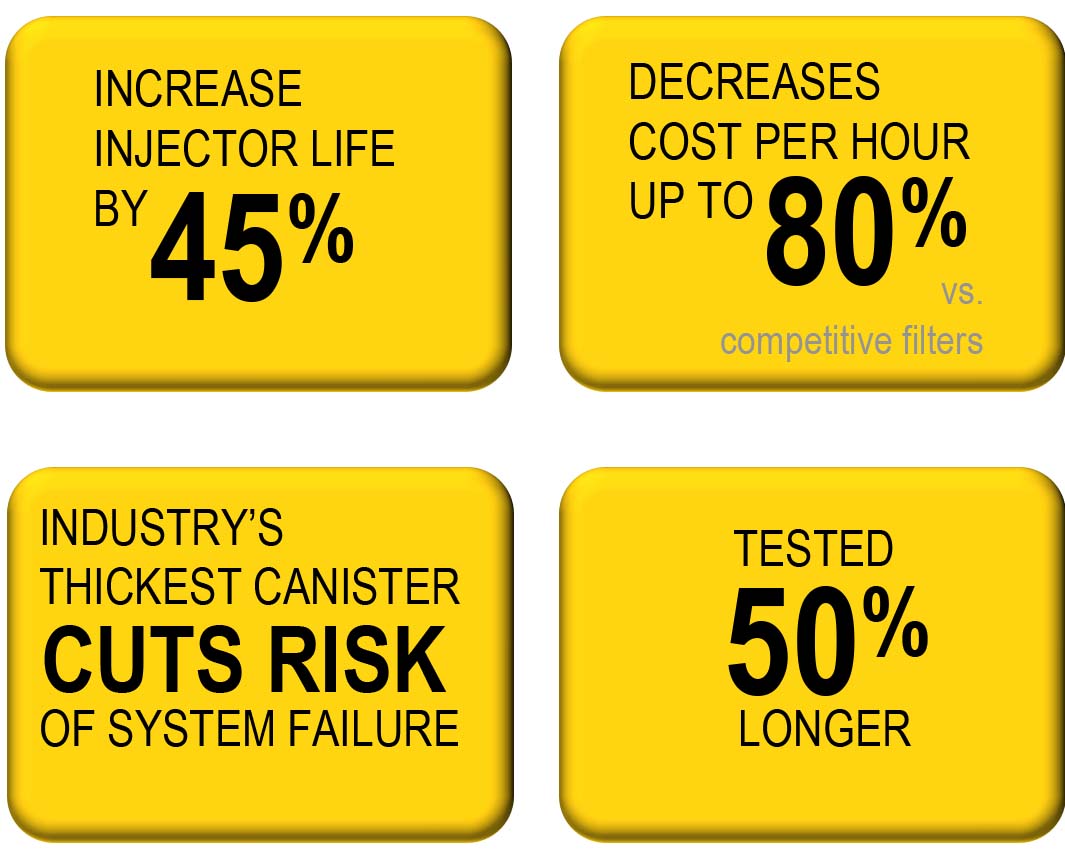

FUEL FILTERS

Capture the small particles that do the

most damage to engine parts.

Terms & Conditions

- • Applicable only to Cat equipment owners.

- • Applicable only to specific Cat filters; customer can provide their list for quotation.

- Minimum purchase of (S$6,000 / S$20,000) per transaction is required for special price promotion (at Nett Value exclude GST).

- Parts purchased under promotion are non-returnable and non-refundable.

- Parts are subjected to prior sales. Any miscellaneous charges, such as airfreight or emergency charges, will be incurred by customers unless order under non-emergency basis.

- Order must be placed with sales person directly. Not valid with other promotions, discounts or parts.cat.com (online sales).

- Offer valid til 26 June 2026 or while stock last. Any back order parts that are confirmed and delivery after 26 June 2026 will be subjected to the new pricing.

- Other T&Cs for quotation and sales order apply.

- Tractors Singapore Limited reserves the right to modify or cancel the program anytime.